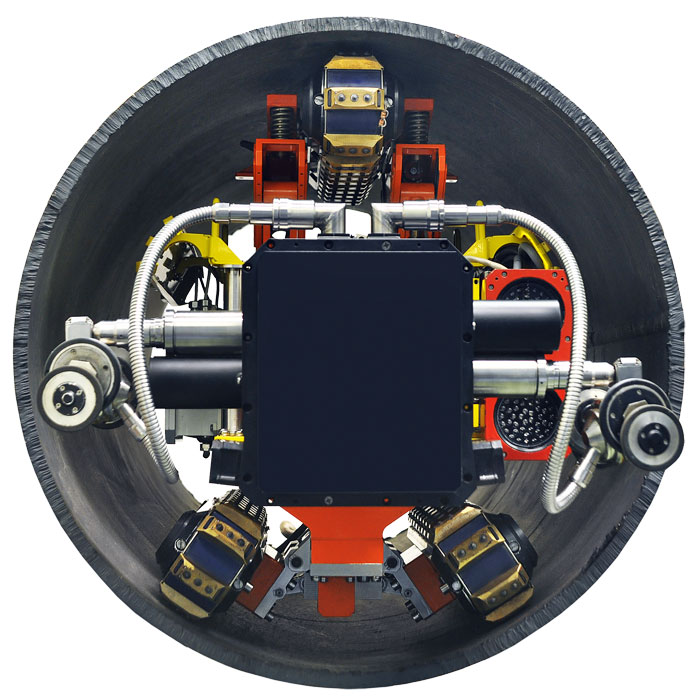

Diakont has developed a fleet of in-line inspection robots, called RODIS crawlers, to support the asset integrity of gas and liquid pipelines by detecting and measuring internal and external metal loss, corrosion, and various other anomalies. Not only is this collected data highly precise, but it can be observed in real time while the inspection is taking place, providing immediate access to crucial information that utilities and pipeline operators require to facilitate integrity management programs and meet federal pipeline safety standards (49 CFR Part 192 and 195). From a single access point, our crawlers can be launched and retrieved to inspect up to 1,800 feet of pipe. Diakont’s fleet of robotic ILI tools can accommodate pipelines ranging from 8” to 55” in diameter.

Diakont’s RODIS crawlers minimize or eliminate excavation requirements by travelling to crossings or other target pipe sections from convenient access points close to grade level. In addition to the line types described above, our tools perform pipe inspection on sections previously considered “unpiggable,” including:

Combining multiple detection approaches in a single inspection unit improves anomaly identification and eliminates the need for separate, costly inspections. As such, each of Diakont’s ILI robots is equipped with multiple NDE sensory technologies, including:

Diakont is known for its commitment to safety as our first priority. Consequently, our robot crawlers are explosion-proof, and as an additional safety precaution, we also offer nitrogen N2 purging services to confirm, monitor, and maintain an O2 concentration of below 10% prior to and during inspections for liquid pipelines.

Partnering with Diakont will ensure maximum value for your integrity management program. Our expert team of project managers, ILI engineers, and NDE technicians will guide you through the entire inspection process, meeting or exceeding your schedule requirements. Following each inspection, Diakont delivers a complete pipeline features list, including absolute thickness measurements, weld locations, weld defects, pipewall anomalies, and information about all fittings. The Diakont inspection group will support your pipeline and girth weld inspection needs, from pipeline cleaning, excavation, spool removal, verification digs, and more.

Additional reasons to choose Diakont as your inspection vendor include:

Common RODIS Crawler Inspection Applications

High-Accuracy Data on Tough-to-Access Lines

Advanced, All-in-One NDE Sensory Capability

Common Pipe Anomalies Detected

The “Belt and Suspenders” Approach to Safety

World-Class Service, from Start to Finish

Downloads

Robotic In-Line Inspection Factsheet